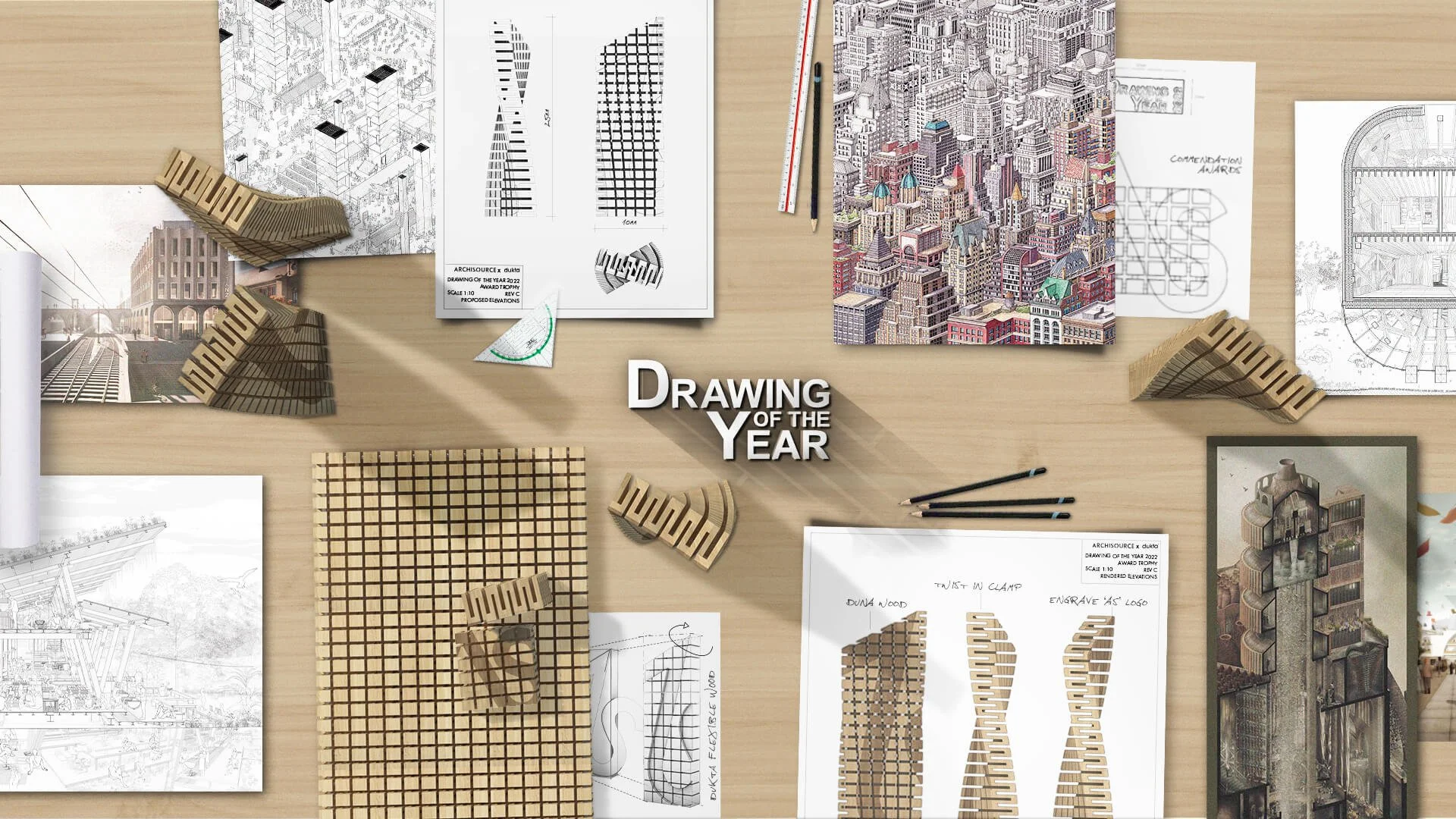

TROPHIES

ARCHISOURCE | DUKTA

2022 TROPHIES

OUR COLLABORATION

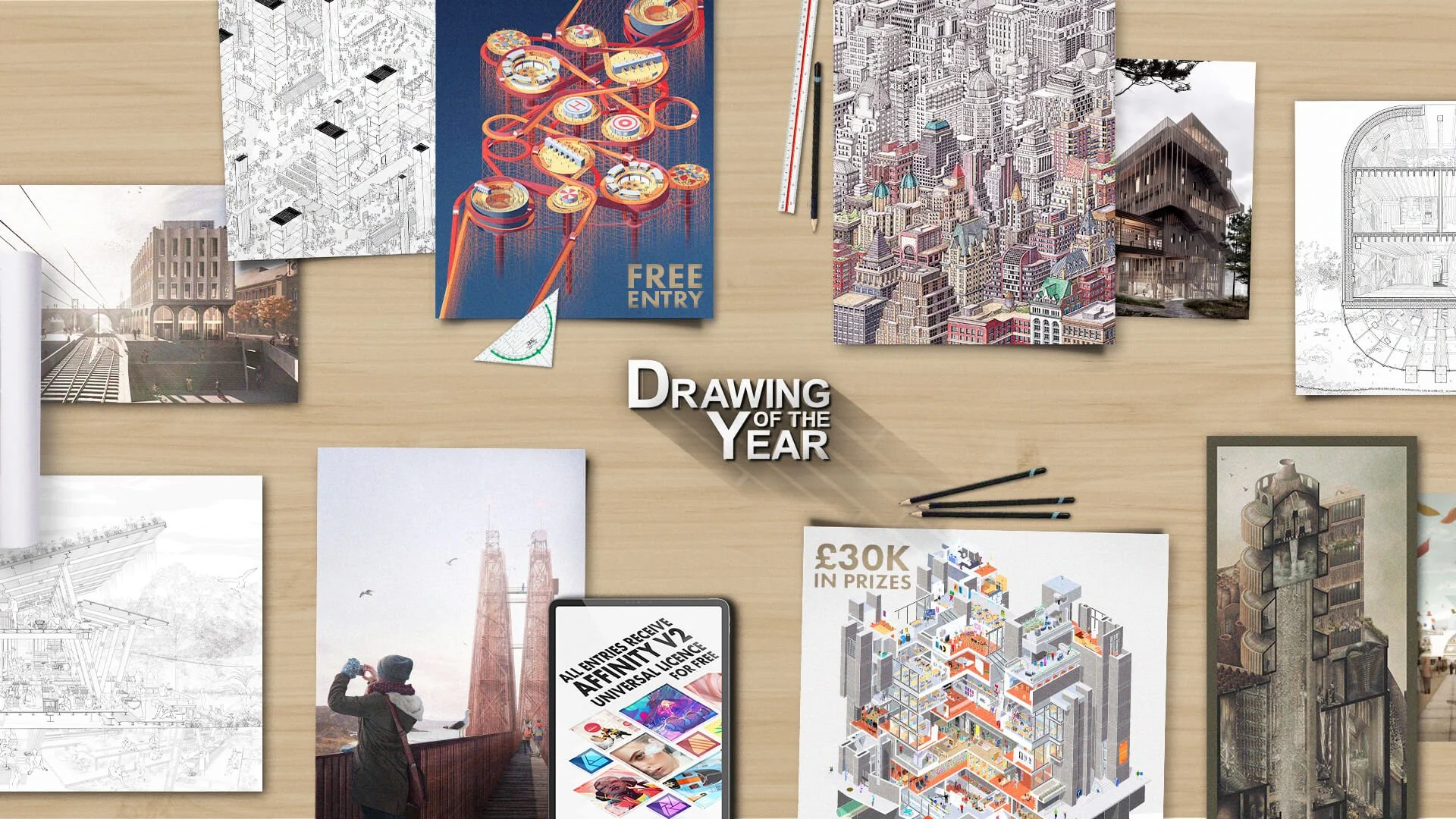

The Drawing of the Year 2022 award trophies were designed in collaboration by Archisource and dukta using their unique flexible wood.

Archisource: “We wanted to create trophies that celebrated the unique qualities of dukta’s flexible material. The design of the awards utilises dukta’s flexible engineered wood and their patented incision process to create unique twisted trophies for this year’s Drawing of the Year competition. The innovative materiality and its flexible characteristics make for quite special trophies which subtly oscillate and sway whilst holding - giving a natural and ‘living’ quality to the trophies.

Sustainability has always played a significant role in designing each year’s award trophies; utilising dukta’s innovative and sustainably sourced engineered wood has been an inspiring process in how you can manipulate and push wood beyond its preconceived capabilities and typical forms. The trophies have been crafted to celebrate its flexibility and materiality - but we also hope it inspires others to experiment and perhaps push materials beyond their traditions.”

Trophies will be awarded to the winners of each award category. Physical commendations will also be awarded to selected standout works.

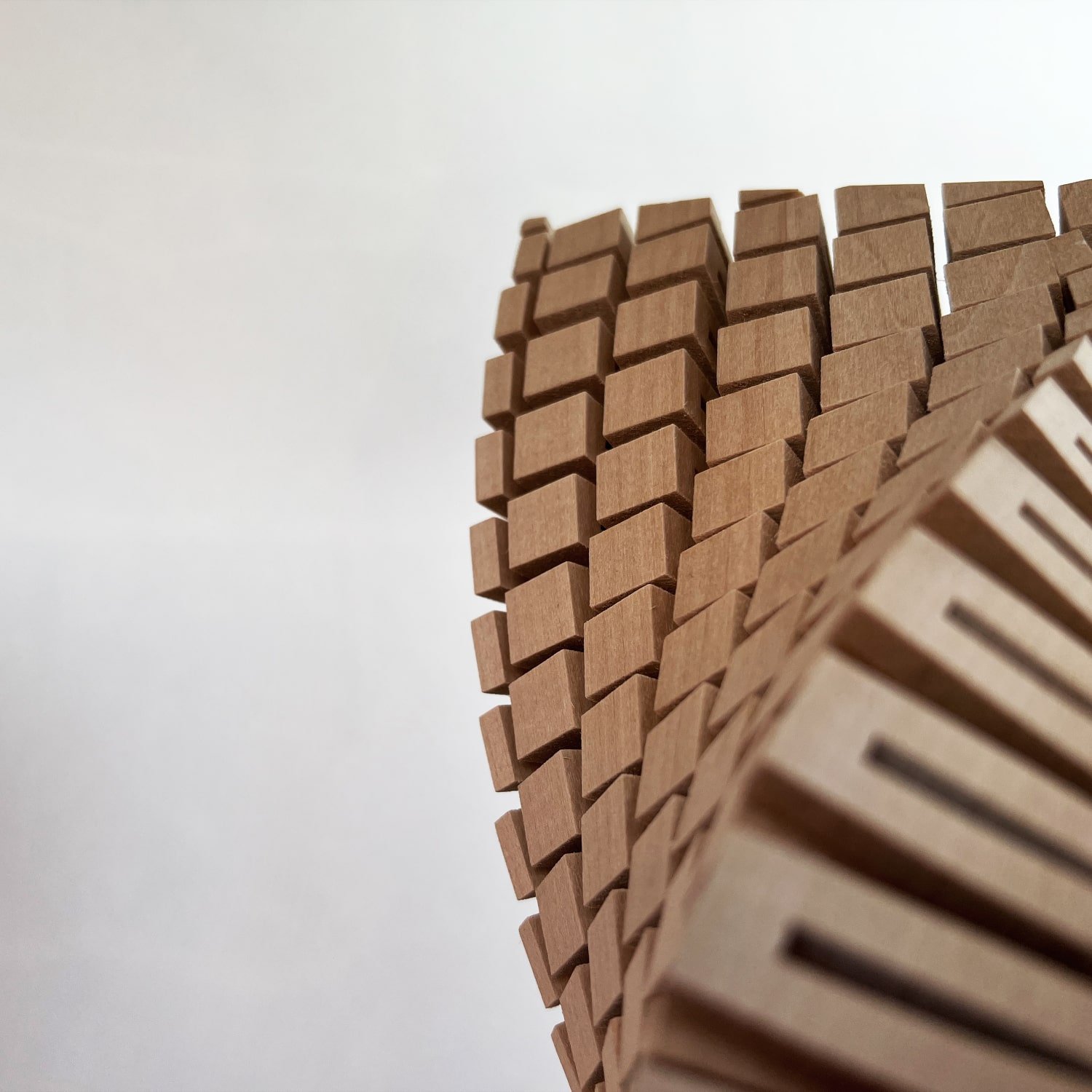

PROCESS

Wood and engineered wood are made flexible with a patented incision process. Complex incisions allow textile-like properties plus create transparency and sound absorbing properties unexpected from wood products.

The design utilises dukta’s Duna wood materiality which allows the face surfaces of the trophies to bend in two directions - which typically cannot be made out of a flat material. The idea was to create objects that showcase this ability to 'double curve' the face surfaces.

Derived from our Archisource ‘AS’ logo, an abstracted AS profile formed the elevation and top pitch. The trophies were then cut into separate segments and laser etched.

The segments were then soaked in water to soften the wood to allow for ease of blending and manipulation. Each segment was then clamped within a custom-made twisting jig and twisted to the desired rotation.

The segments were left to dry until set. See the photos of the trophies below!

DUKTA

Based in Zürich, Switzerland, dukta has it’s roots in wood bending experiments. During a training course led by Serge Lunin in 2007, Christian Kuhn had the idea to create a lounger made from curved wooden elements. Together they tested alternatives including steam bending and gluing layers together but found that certain arrangements of incisions gave the wood a great deal of flexibility. Together with the Institute for Design and Technology at the ZHdK, the architecture, wood and construction departments at Bern University, they started an 18-month CTI research project to explore the possibilities and production processes of flexible wood.

From these humble beginnings, dukta GmbH was founded in 2011 and patented the incision technique internationally. Now headed by the father and son team of Serge and Pablo Lunin, dukta works with licensed partners throughout the world. The company has won numerous design awards including German Design Award 2018 and Interior Design’s Best of Year in 2018.

Serge Lunin is a wood expert and designer having trained as a carpenter and cabinet maker, and has been a lecturer at ZHdK since 1990. He has been working on the dukta project since 2007.

Pablo Lunin is a product and industrial designer. After studying as a product and industrial designer Pablo worked for two years on developing new chocolate products for a multi-national company. In 2015 he joined his father’s company, dukta, and started the license business with producing partners and the distribution of the flexible wood panels.