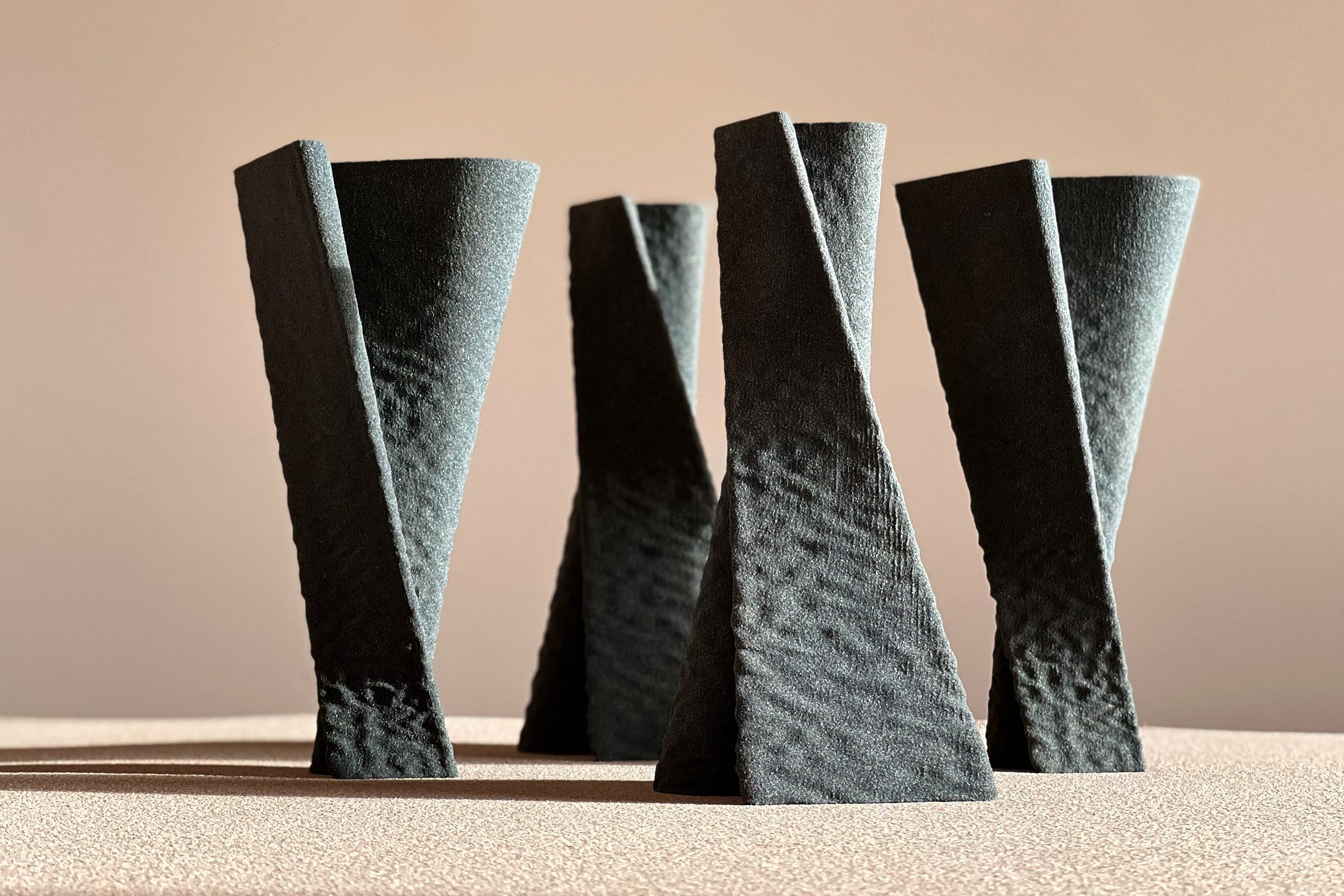

AWARD DESIGN

ARCHISOURCE X SANDHELDEN

2021 AWARDS DESIGN COLLABORATION

Images © Archisource 2022

ABOUT SANDHELDEN

MATERIAL

Sand as a material

SANDHELDEN change the perception of sand. In cooperation with international creatives from all industries, they create objects and products in this unique material.

TECHNOLOGY

3D Printing Technology

The SANDHELDEN process enables the realization of projects of all kinds. 3D printing technology is not limited to conventional restrictions such as undercuts or quantity.

Sand can be brought into any imaginable shape. The resulting flexibility in production can easily be used for individual items as well as large series.

The complete procedure is divided into different processes. The first step deals with the 3D modelling. Based on the requirements and ideas, the design is coordinated and a printable 3D file is created. The 3D printing process is then initiated with this file. SANDHELDEN uses professional 3D industrial printers.

In a layer process, the selected shape is then printed layer by layer with high-precision nozzles in the highest quality.

SANDHELDEN uses the "binder jetting" process as a 3D printing technology.

Two grains of quartz sand are placed on top of each other per layer. So that the grains of sand stick together, a binder is partially applied, which leads to a bond. In comparison to other 3D printing processes, this process does not use high temperatures.

In the third step, the printing blank is carefully exposed. It is cleaned with air pressure until any loose grain of sand has been removed from the surface.

SUSTAINABILITY

SANDHELDEN is sustainable

SANDHELDEN have set themselves the goal of building a stable and fair infrastructure that is promoted by constant technical innovations. Any thoughtful and sustainable forms of consumption and production are very important to them.

Regionality in production and raw materials

Sustainability begins with the raw material quartz sand. It is originally sourced in Bavaria, which is the home of SANDHELDEN.

Together with local manufacturers, suppliers and post-prouction, all of the various and diverse products are 100% regionally made.

Resource-saving production process

3D printing is an additive manufacturing process that is energy and resource-efficient.

We avoid any material waste by completely recycling our natural raw material of quartz sand so that it can be returned to our production cycle.

Sustainable research with recyclable microplastics

A major area of interest for SANDHELDEN is research on and with other recyclable materials in combination with the 3D printing process.

Within several funding programs of the Bavarian State Ministry for Economic Affairs, Regional Development and Energy, and in cooperation with the Fraunhofer Institute IGCV, SANDHELDEN is investigating the use of recycled microplastics in additive manufacturing and the possibility of serial production.

The reused plastic is mainly microplastic from the ocean. This is applied in powder form and bound in layers during the printing process.

OUR DESIGN COLLABORATION

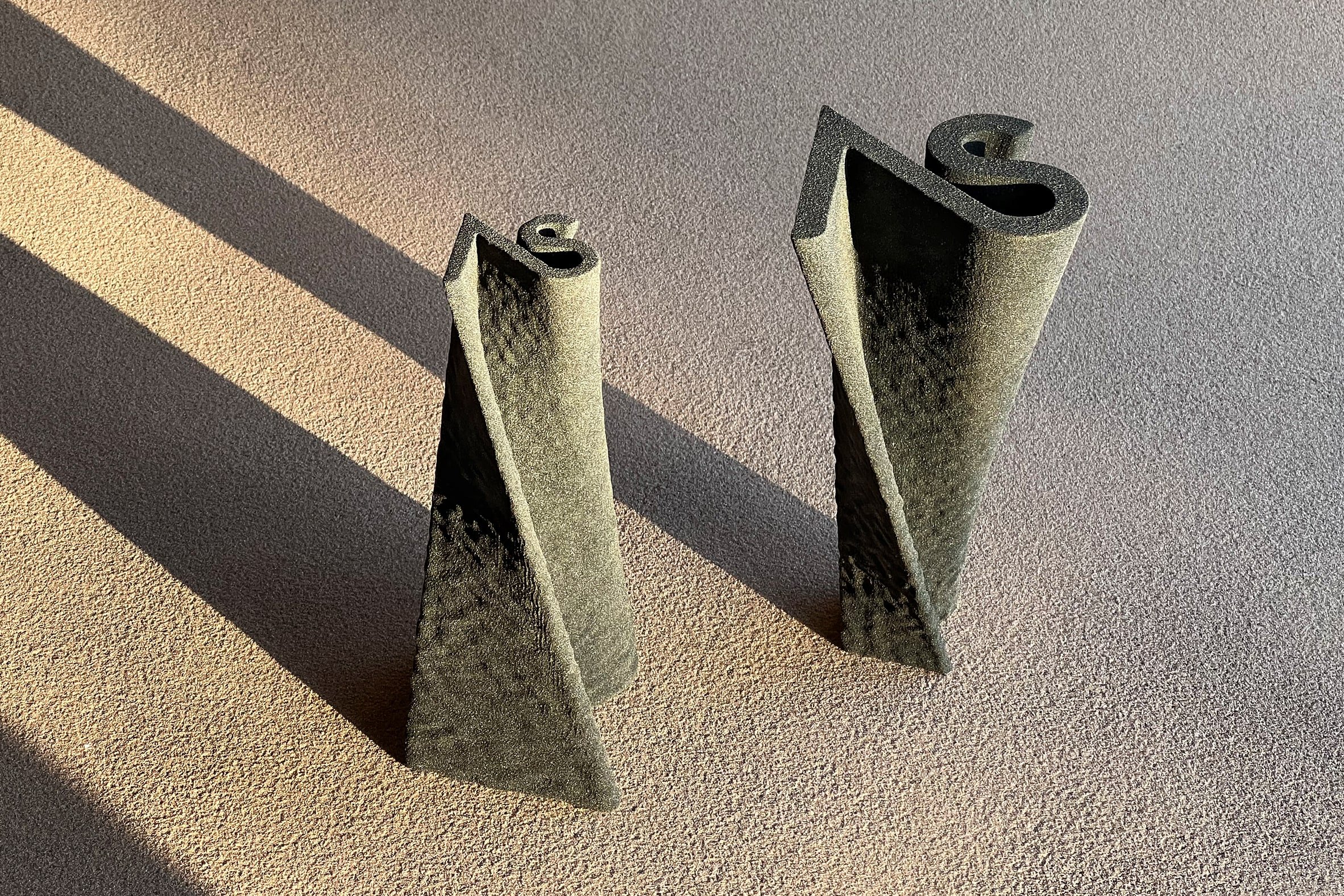

The Drawing of the Year 2021 Award trophies have been designed in collaboration with SANDHELDEN and are crafted from sand through binder jetting

The Bavarian design collaborator and manufacturer SANDHELDEN has used locally sourced sand to create this year's Archisource Drawing of the Year Awards trophies and Commendation Awards, which will be awarded to all the winners in this year’s competition.

Sustainability begins with the raw material quartz sand, which is mined directly in Bavaria. Together with a Bavarian plant manufacturer, customized products are created in the same region. This reduces transport distances and the related greenhouse gas emissions. Post-production, such as hardening and coating, is also handled locally. Thus, products from SANDHELDEN are 100% "Made in Bavaria". Sustainability is also playing an even more important role with regard to binders, for example by using inorganic binders.

SANDHELDEN combines high-quality design and natural material with the unlimited possibilities of 3D printing. The result is a unique product and service range in the design and art industry that will revolutionize these markets in the long-term.

Unlike classic manufacturers, SANDHELDEN considers itself a cooperation partner for artists and designers. The company supports the entire project - from the first sketch to the final object.

SANDHELDEN continuously invests in the expansion of its material portfolio to include sustainable and recyclable raw materials. The aim is to achieve a higher level of individuality and a maximum environmentally friendly process.

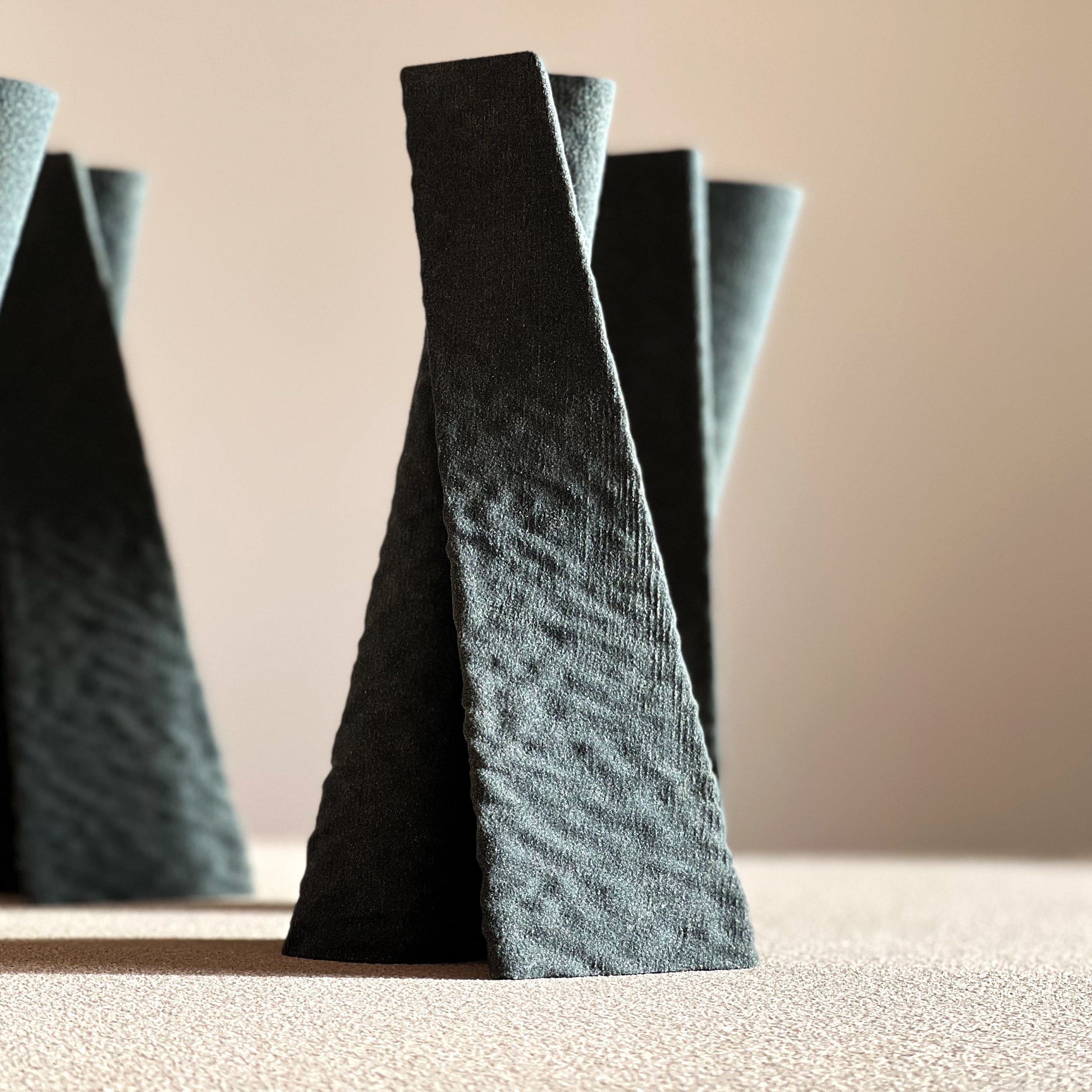

The AS-shaped trophies are crafted in sand through a process of binder jetting, the Awards explore the idea of expressing sand at its fullest - „Back to the origin“.

The twisted trophies express flowing dynamics, endless paths and eroded forms drawing inspiration from capturing the textures and nature of sand through to the physical forms of the 3D Awards.

Archisource:

“We are truly inspired by the work and process of SANDHELDEN and their sustainable ethos was a driving force behind this collaboration. SANDHELDEN’s method of manufacturing is a unique and exciting process and one that we wanted to showcase through these Awards.”

SANDHELDEN´s designer Carlos del Castillo worked in collaboration with Archisource to design and produce trophies for the Drawing of the Year 2021 Awards, along with creating Commendation Awards (all of which are completely unique in design!)

SANDHELDEN’S PROCESS

Images © SANDHELDEN

Copyright Archisource © 2023